Diamond saw blade for cutting reinforced concrete

SANG diamond saw blade strength:fast cutting with long lifespan,save energy in power and stone. Fast cutting with long lifespan Save energy in power and stone

Brand:

SANGItem No.:

SG-NEW-CONCRETE-111Payment:

TT100%,Western Union,Paypal,Money Gram,etcProduct origin:

Fujian ChinaShipping port:

Xiamen or Guangzhou PortLead Time:

7~14 days after payment recievedMOQ:

5pcs16 Inch Premium Arix Segment Laser Welded Diamond Saw Blade for Concrete Brick Block and Masonry Dry or Wet

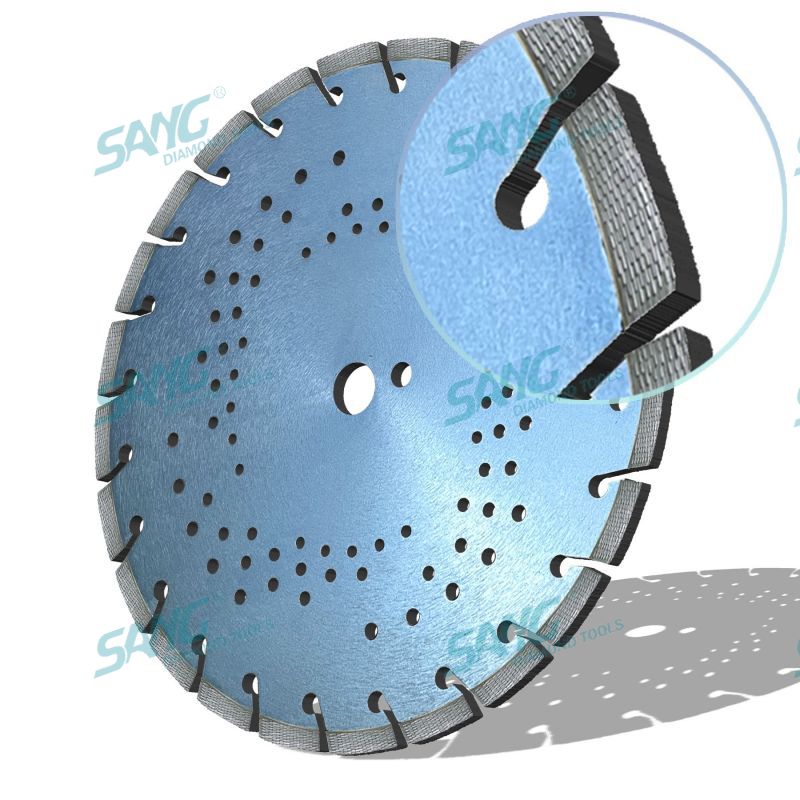

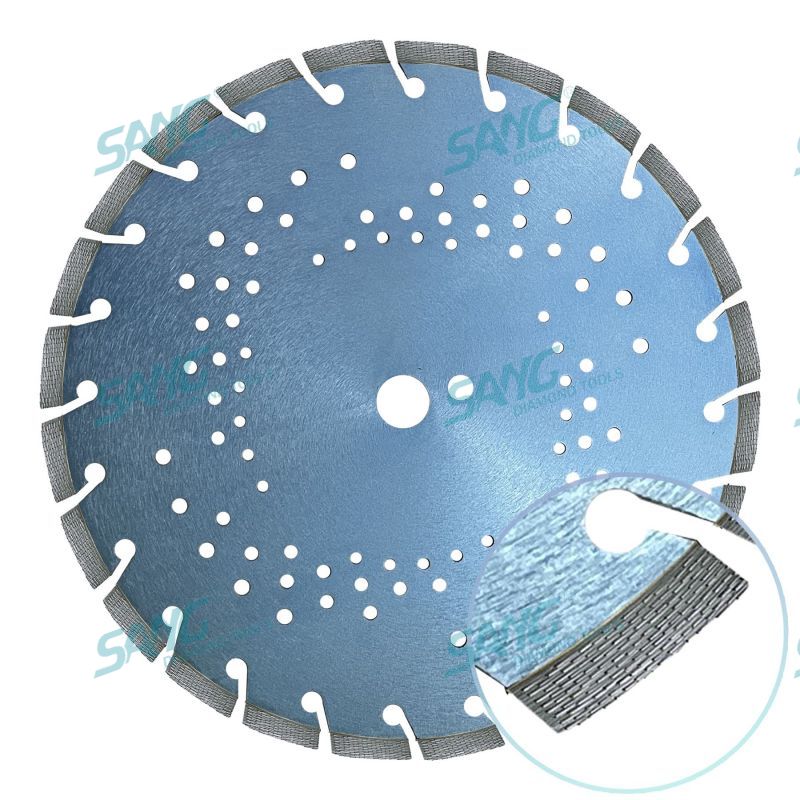

Arix segments: Arix is a type of diamond segment technology that enhances cutting speed, performance, and lifespan. It typically consists of multiple layers of diamonds arranged in a specific pattern, offering improved cutting efficiency.

Laser welded: The segments are laser welded to the blade's core, ensuring a strong bond and reducing the risk of segment loss during cutting.

16-inch diameter: The blade has a diameter of 16 inches, which is suitable for larger cutting jobs.

Wet or dry cutting: The blade is designed to work with both wet and dry cutting methods. Wet cutting typically provides better cooling and dust suppression, while dry cutting offers convenience in certain situations.

Suitable for various materials: This blade is specifically designed for cutting concrete, bricks, blocks, and masonry. It is engineered to withstand the challenges of these materials and provide efficient cutting performance.

Other specifications on request available.

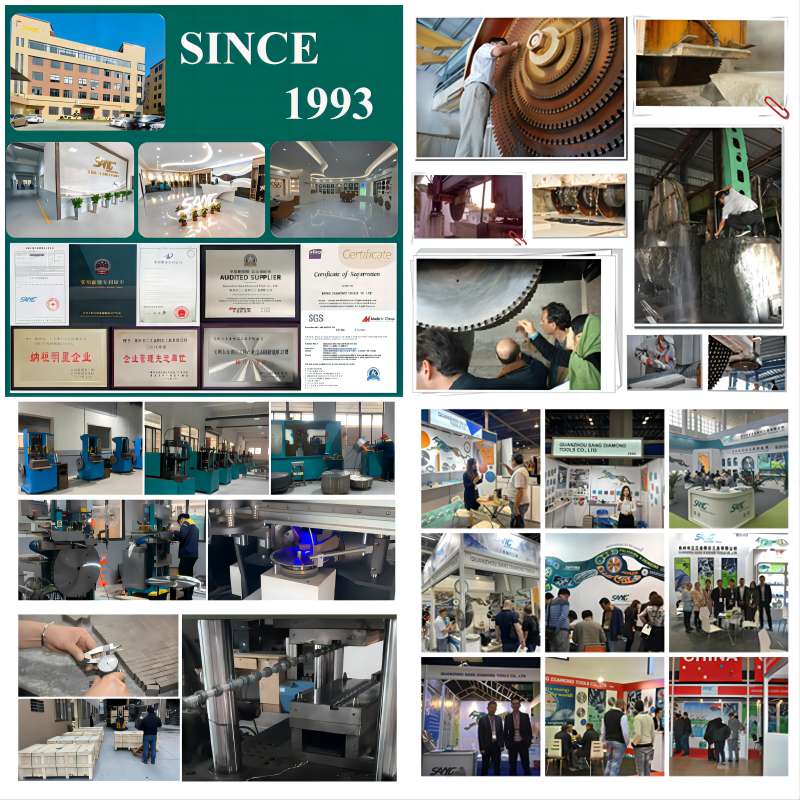

ISO9001&Gold Supplier

Factory=Quality Control=Competitive Price=Own technology=OEM

How does the laser welding process contribute to the blade's overall strength and longevity?

The laser welding process used in diamond saw blades contributes significantly to their overall strength and longevity. Here's how:

Strong bond: Laser welding creates a strong bond between the diamond segments and the blade's core. This bond is essential because it ensures that the diamond segments remain securely attached to the blade during the cutting process. A strong bond reduces the risk of segment loss, which can lead to inefficient cutting and potential safety hazards.

Heat distribution: Laser welding allows for precise control of the heat distribution during the welding process. This control ensures that the heat is evenly distributed, preventing excessive heat buildup that could potentially damage the diamond segments or the blade's core. By maintaining appropriate temperature levels, the blade's structural integrity is preserved, enhancing its overall strength and longevity.

Enhanced durability: The strong bond achieved through laser welding enhances the blade's durability. It enables the blade to withstand the high stresses and forces encountered during cutting operations. This durability translates into a longer lifespan for the blade, reducing the need for frequent replacements and saving costs in the long run.

Reduced vibration and noise: Laser-welded diamond saw blades often exhibit reduced vibration and noise levels during cutting. The precise and strong bond between the segments and the core helps to minimize vibrations, resulting in smoother cutting operations. Reduced vibration not only improves cutting accuracy but also reduces operator fatigue and enhances user comfort.

Overall, laser welding contributes to the blade's overall strength and longevity by ensuring a strong bond, even heat distribution, enhanced durability, and reduced vibration. These factors combine to provide a reliable and long-lasting saw blade that can withstand the demanding cutting applications in concrete, bricks, blocks, and masonry.

FAQ

1.Are you a manufacturer or trading company?

We are a 31 years manufacturer.

2.How to prove your quality?

We use E6 diamond,Dipea steel wire, passed ISO9001 and SGS,strict quality control and skilled workers.

3.What should I do if the products is not suitable for the market?

Giving us the detailed report first,then we analyze the reason,try to find the solutions.

If it is our problems,we will give you new products.

4.Do you provide free samples?

Small sample is welcomed.But,usually we don't provide free samples.

5.Can you provide OEM/OEM services?

It is ok.

6. Any question about 16 Inch Premium Arix Segment Laser Welded Diamond Saw Blade for Concrete Brick Block and Masonry Dry or Wet, please kindly let me know!Thanks!

24/7 via fax, email or phone.